The current manufacturing module of Odoo has certain missing features-

1. We don’t have configuration for multiple Raw Material Location

2. Issuing products to Production (Semi-finished) location is missing

3. Cannot select another BOM for Manufacturing Order created automatically from Sales Order

4. There is no track of Estimated and Actual Cost

5. No field to track total cost of production

In order to enable creation of Manufacturing Order from Sales Order and also automatic generation of Purchase Requisition for raw materials, the configuration steps is as follows. Also, to achieve the above listed advanced features customization have been done. Here are the steps

- Finished Product Configuration– The product is defined as “Stockable”. Costing method should be set to Standard (so that the accounting impact pulls the price from Manufacturing Order). Select routes as Make to Order and Manufacture.

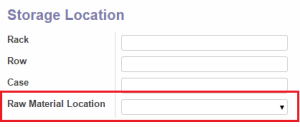

- Raw Material Product Configuration– The product should be set to “Stockable” if stock management is required else set to “Consumables”. Costing method should be set to Average (we are assuming here that raw materials will always be bought from Supplier). Select routes as Make to Order and Buy. Default Raw Material location of this product can also be configured under Inventory tab.

- Bill of Material Configuration– Goto Manufacturing -> Products -> Bill of Materials in order to define BOM for every product.

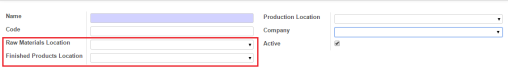

- Routing Configuration– Next, we define different operations through which the raw materials will go through. We also specify default Raw Materials and Finished Products Location. Make sure right Semi Finished Location is also selected. Once routing is defined we attach it to BOM. Here, we have customized to allow users to add default Raw Material and Finished Product Location so that when Manufacturing Order gets created it pulls the location from here.

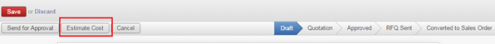

- Estimating Cost– A new button is provided in Sales Quotation. Based on this estimated cost salesman adds profit margin to get the final sale price of the order.

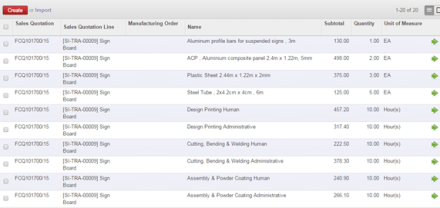

Manufacturing Cost Estimation On clicking, system automatically pulls 2 things-

- Raw Materials defined in BOM and

- Operations defined in Routing

The subtotal and quantity comes from these configurations. User can click on green button to change the quantity (no. of hours) of an operation. The subtotal and total estimated cost gets adjusted accordingly.

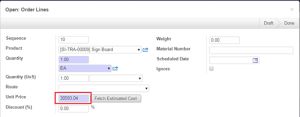

- Fetching Estimated Cost in Quotation Line– A button is provided in quotation line as shown below

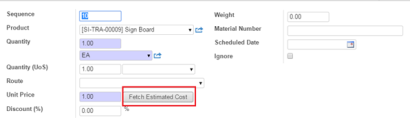

Fetching Estimated Cost When the button is clicked then it asks for Profit Margin and accordingly updates the unit price of the quotation line

Add profit margin to estimated cost The price has been updated-

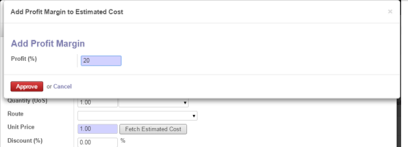

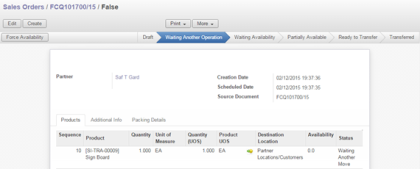

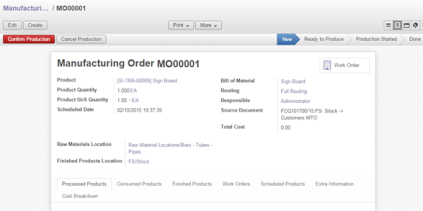

- Manufacturing Order– Finally, when the quotation is converted to order then automatically manufacturing order gets created.At this stage, Delivery Order shows Waiting Another Operation as MO needs to be completed

Delivery Order Waiting Another Operation MO created is in draft state so that user can verify all the details before confirming it. Also, a product can have multiple BOM so make sure right one is selected.

Manufacturing Order in draft state (a) Buying of Raw Material

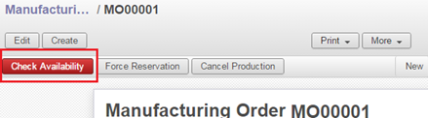

After MO is confirmed, then click on Check Availability to automatically raise Purchase Requisition against the supplier configured in Product Master. If the raw material is already there in stock then click on Force Reservation button as shown in the following diagram

Buying Raw Material Purchase Requisition gets created. The system smartly merges all products into one which is being bought from one supplier and coming into same Raw Material location. The full workflow is followed and we receive all raw materials.

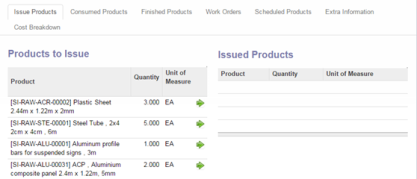

(b) Issuing Raw Materials to Work in Process locations

Before we purchase raw materials, the Issue Products tab shows products in red. But once the product is purchased and available in stock then the color changes to black. Here, the stock move created pulls source location from the Raw Material Location field configured in Product Master. This way each material can have different source location.

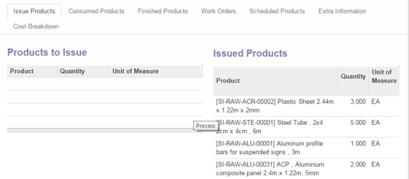

Issue Raw Materials to Work in Process locations We then click on green button to issue them to Work in Process location

Raw Materials Issued to Work in Process location (c) Start Production

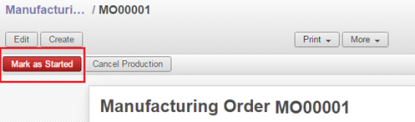

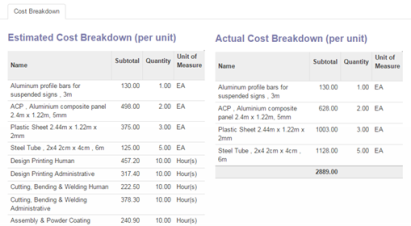

Click on Mark as Started button on the header to start production. This will generate costing of BOM in cost breakdown tab.

Start Production Cost Breakdown tab lists actual raw material costing

Actual Cost Breakdown (d) Process Work Orders

Work Orders tab lists all the operations defined in Routing. Number of Hours field is editable so that user can enter the actual no. of hours spent on each operation. As each work order is completed, Cost Breakdown tab lists the actual costing.

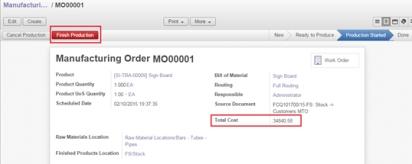

Actual Cost Breakdown (e) Finally when all the work orders are completed then we hit Finish Production. Total cost field shows the actual costing of the product

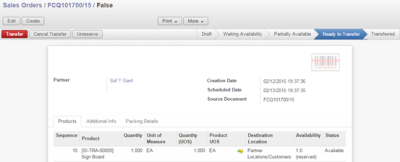

Finish Production The MO state now shows Done. The delivery order state also changes to Ready to Transfer

- Delivery Order– Finally we transfer the finished product to our customer by clicking on Transfer button.

great post! sir, where can i get the customization made on this article?

As of now this module is available only with me.

is it possible to implement the procedure in this article without the “customized module”? if not, how can i obtain it? please advise, thank you.

You need to install my module in order to achieve it.

If you are interested in this module, then please contact me on skype. My ID- aasim.ansari

Hallo Aasim,

Could you please share this module with me.

jakhoeblal@gmail.com

Hello,

I need to understand your requirement first before you start using my module. My write-up is based on specific feature of one of my client.

Hi Aasim,

The solution you described for your customer looks similar as I want to have. Minor changes I could make myself.Please share your module

Hello,

I have emailed you the module.

Let me know if you need further assistance.

Please, can I have copy of the module too, thank you.

May I please have a copy of the module too.

Hello,

If you are interested in this module, please email me you request at aasim333@gmail.com

Hi Aasimansari, can i have i copy from this Module

Can you let me know if the cost of products flows through in the accounting module as well. I have been trying to install odoo for a beverage company that makes their beverage in stages. When I use a BOM and Manufacturing orders, the cost don’t seem to follow the production. So when I look at my balance sheet at various stages of production, the Raw Materials cost don’t follow to WIP and then to Finished Goods. And upon sale the cost don’t flow to Cost of Goods sold. In one of your prior post, you seemed to move the cost of the manufactured from Raw Materials to WIP to Finished Goods through the use of a corresponding stock journal, using, I presume, a separate entry system.

Yes with proper configuration the cost follows. Odoo picks up Stock Valuation account from product category. So, make sure your raw material and finished goods are linked to right category.

Secondly, your work in process location should be of type Production where you can configure Stock Valuation Account (Incoming and Outgoing).

If you are still facing problem we can talk on Skype. My ID is aasim.ansari

Thanks for response. Will have a look again.

Hi aasimansari

Can you maill me this module

My mail id is vadlaerp@gmail.com

I am testing odoo as a replacement for Netsuite and just started working with the BOM, would it be possible to get a copy of your script….

Thank you in advance .

John

Hello,

If you are interested in this module, please email me your request at aasim333@gmail.com

Hi Aasi,

Could you also share this module with me at m.schaekermann@spontaneousorder.de ? Thanks a lot in advance!

Mike

Hi, i’m a student can you also share this module whit me??

pabloitba@gmail.com

thanks!!!

Any change the module availability is for v9 as well?

I developed it for version 8

Hi aasimansari.

Thanks for the info and for your time.

I’m looking for information, to obtain the real cost of production in Odoo 8.

That is why I found your blog.

I would like to test your module. If you would be so kind as to provide it. Or, tell me as I can get.

I appreciate your time and support.

Thanks in advance.

Best regards.

If you are interested in this module, then please send me a request on aasim333@gmail.com

Hi Aasi,

Could you also share this module with me at xguerra.e@gmail.com ?

Thanks for this!

Xavier

Hi Aasim Ansari,

Thank you for the module.

Cheers,

Munesh

hello, good idea! cand you share you module? buron@tomasburon.cl

Hi Aasi,

Great job !

Could you share this module with me at mickael@myfood.eu ?

Thanks in advance!

Mickaël

I need it too.. sanatpanda90@gmail.com

Hi, Aasim,

I’m interested in the module that you developed, could you share to test it ?. Thank’s

rescolas@hotmail.com

I’m interested in the module that you developed, could you share to test it at rescolas@hotmail.com ?.

Thank´s

share me abdalwhab.babikr@gmail.com

Hi Aasim,

Can i have the module, please? Thank you very much in advanced.

nicole.khor@on.net.my

can you please send me the module @ anoopputhukkudy@gmail.com

can you please send me this module @ anoopputhukkudy@gmail.com

Hello Aasim, I would need your module to modify default location (raw material & finished products) in a production order.

Can you please send me the module to baudoin.kopp@gmail.com?

Thanks a lot in advance

Baudoin

Hello, can you share your module?

My adresse is baudoin.kopp@gmail.com

Br

Baudoin

Hallo Aasim,

Could you please share this module with me with this Email

ehgharably@hotmail.com

Hallo Aasim,

Could you please share this module with me with this Email

flxe2@yahoo.com

Hallo Aasim,

Could you please share this module with me with this Email

yasmin@cloudypedia.com

Hi Mr. Aasim

Would you like to share this module with me my email is

email4razak@gmail.com

can you please send me this module @ mudasir.techloyce@gmail.com